Food spoilage is a constant concern for both consumers and the food industry, with bacteria, yeast, and mold being the main culprits. These microorganisms find their way into food through various sources, including manufacturing equipment and processing plant environments. The traditional way to combat food spoilage is by using preservatives or chemicals. However, researchers at Norwegian manufacturing company Elopak have developed an innovative and chemical-free method to prevent food spoilage using a spectrometer.

Using Spectrometry to Detect Spoilage Organisms

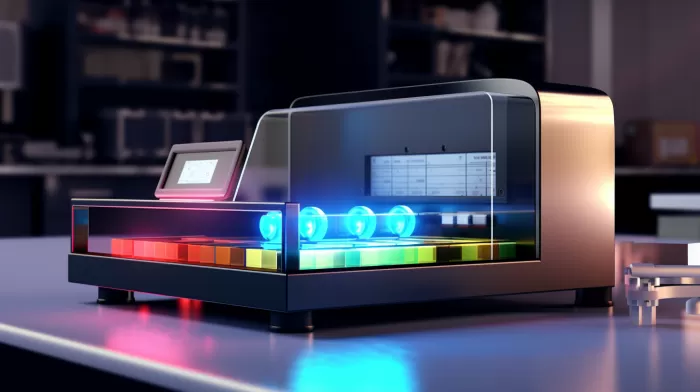

Spectrometry is a method that involves the measurement of properties of light interacting with a sample. This allows for a rapid and highly sensitive way to analyze and identify different substances. The researchers at Elopak have successfully applied this method to detect and trace spoilage-causing microorganisms, such as bacteria, yeast, and mold, back to their place of origin.

Henri-Pierre Suso, a researcher on the project, explains that spectrometry is “a very precise and high-capacity method, with the additional advantage that technicians don’t need to be specialists in mycology in order to identify the microorganisms.”

By identifying the source of contamination, manufacturers can troubleshoot the root of the problem, rather than merely treating food to prevent spoilage. This not only saves money but also gives consumers peace of mind that their food is free of chemicals often used to fight spoilage.

The Importance of a Microbial Database

To truly capitalize on the power of spectrometry and ensure the most accurate results, the researchers are compiling a database of 20,000 spectral profiles of microbes. These spectral profiles essentially act as “fingerprints” for the bacteria, yeast, and mold, allowing for quick and accurate identification.

As Suso explains, “Once we have that database, we can simply compare the spectral profile of the microorganisms found in the food industry with the profiles in our database and quickly identify the source of the contamination.”

A Cost-effective Solution for Food Manufacturers

One of the most significant advantages of this method is its cost-effectiveness. According to the study’s authors, spectrometry provides an efficient, effective, and economical solution for food manufacturers.

Traditional methods for fighting food spoilage, such as chemical additives and preservatives, can be expensive and have a negative impact on consumers’ health and the environment. By directly addressing the source of contamination using spectrometry, food manufacturers can save both money and resources, plus provide a healthier and more sustainable product for consumers.

Future Applications and Developments

As spectrometry technology continues to advance and the database of microbial spectral profiles grows, the potential applications for this method are vast. Not only can it be used to address food spoilage concerns, but it can also be applied to other industries where contaminants are of concern, such as pharmaceuticals, cosmetics, and more.

Additionally, as microbial databases expand, there is potential for the development of portable spectrometers that could be used in small-scale food processing facilities or even at home to test food for spoilage.

A Healthier, More Sustainable Future for Food

The development of chemical-free methods for preventing food spoilage, such as spectrometry, ultimately contributes to a healthier, more sustainable food industry. By identifying contaminants at their source and eliminating the need for unnecessary chemicals, food manufacturers can provide consumers with fresher, safer, and more environmentally friendly products.

In a world where food waste is a significant concern, innovative solutions like spectrometry offer a promising way to ensure the longevity and safety of our food supply. It not only benefits the food industry but also contributes to a better future for consumers and the planet.